New to the Machine Industry? Here’s What to Expect

November 19, 2021The machine industry has been a fundamental pillar of manufacturing from the 1st to the 4th industrial revolution. The growing digitalization of manufacturing is shifting the way machines are built and designed.

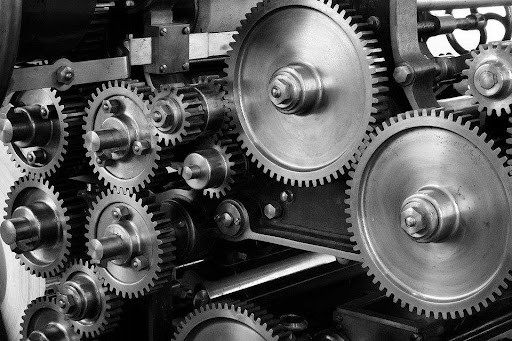

A machine utilizes power to conduct an action or task and control movement. It lowers the amount of human labor needed to finish the job.

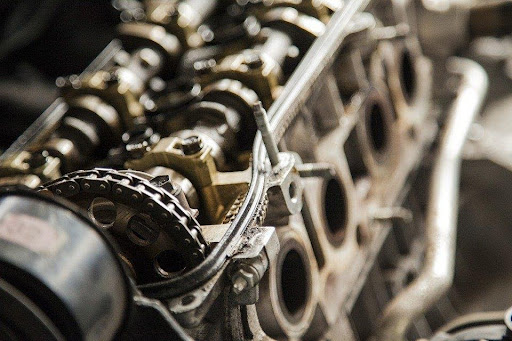

In a regular machine, a mechanism activates the actuator. This will apply movement and force. In addition to that, machines can be mechanical systems. This includes sensors and computers to track and control output.

The concept of simple machines has been around for many years when Archimedes invented the concept of mechanical advantage in the lever.

Archimedes utilized this invention to operate simple tools using screws, pulleys, and levers. After that, machines have been powered by various things. This includes electricity, thermal, chemical, natural forces, people, and animals.

The machine industry was the driving force for the 1st industrial revolution. Many years ago, motorcycle and car machine factories were constructed.

The establishment of machinery resulted in great industrial progress in key sectors. This includes process industries, transport, automotive, and aerospace.

Today, most workplaces utilize some sort of machinery. However, a lot of people are not exposed to the tools that create the products they utilize.

Table of Contents

Sustainability Is the Future

For those who don’t know, the machine industry has long been one of the major contributors to pollution in the environment.

With new management that focuses on science and the environment, people should expect that there will be efforts to make the machine industry more sustainable through more efficient factories.

This will include focusing on cutting back on the high volume of waste in the industry and offering green jobs.

A distributed network of energy-efficient, local, and smaller factories can lower energy consumption by shortening transportation routes to clients.

Aside from that, it also helps lower waste from fewer defective components, getting rid of our reliance on human operators, and lowering the overall carbon footprint in the industry.

The machine industry is an industry that is constantly evolving. Unfortunately, most of the changes are received at a slow and steady pace.

With the new management in 2021, people will start to see the evolution of industrial valves manufacturer that are more adaptive and responsive to both consumers and markets.

Work Smarter

According to the data gathered from their operations, the machine industry is working to become more profitable.

According to them, they’ll achieve this through improving visibility and precision in the supply chain and lowering inventory expenses.

One method to enhance processes is to move from a push-based to a pull-based production system. This improves the ability of the manufacturer to respond to the demands of its clients.

Aside from that, it also helps with the demand predictability of the market.

To help make decisions on how to manufacture a product, the machine industry is turning to the IIoT (Industrial Internet of Things).

The IIoT also helps determine how production expenses can be minimized and how downtime can be lowered.

Collaboration between facility workers can help companies to lower the time to market, produce better processes, and generate smarter machines.

Internationalization is also helping the industry. The reason for this is that manufacturers are knowing DIY and learning methods from other nations.

The machine industry is working to generate easy-to-maintain, better, and smarter machines using automated tools according to details obtained from the IIoT.

This enables machine manufacturers to be more profitable.

Design

Since machines last for a long period, the machine industry needs to guarantee that they design with obsolescence in mind.

Doing so will help the machine stay functional for a long period. Designers can analyze procurement details and avoid choosing parts that are close to obsolescence.

Being strategic about parts choice can have a huge influence on product lifecycle and guarantees that the machine is easy to maintain.

Machines are designed using simulations and models. This can check usability, cost, performance, and more to guarantee the product is effective and reliable.

More prototypes are becoming digital. This can increase the speed of the process and enable real-time testing and simulation.

Aside from designing for obsolescence, the machine industry is designing for digitalization. Their clients are going through fast change as we enter Industry 4.0.

Today, people are demanding data-driven and smart equipment that can link via the internet or Bluetooth to other manufacturing systems.

These pieces of machinery can be linked from day one. This allows early detection of breakdowns and quickly prevents machine downtime and lowers repair expenses.

High-Value Market

The machine industry is thriving. The machine industry in the United States includes around 20,000 companies that generate more than $350 billion combined revenue each year.

In the machine industry, the global market was valued at around $115 billion in 2017. The Asia Pacific is a leader in the machine industry.

A Huge Industry

The machine industry encompasses a couple of major sectors. This includes commercial refrigeration equipment, HVAC, metalworking machinery, service and commercial industry machinery, industrial machinery, mining and construction machinery, and agriculture.

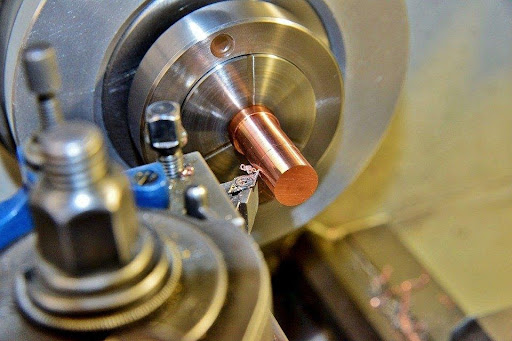

The complicated machinery manufacturing procedure counts on a couple of manufacturing methods. This includes machining, forming, bending, stamping, and forging for individual metal components.

The components are then combined using methods such as assembling and welding. A machinery manufacturing facility will utilize a range of metal forming and manufacturing techniques to create various parts of the machine.

A huge part of the industry falls into metalworking machinery manufacturing.

If you want to visit these types of industries, make sure you always bring hand sanitizer with you to stay clean and safe all the time.

Conclusion

The machine industry is vast. There are a lot of things you need to know if you’re new to it.

The things that we’ve mentioned above are simply some of the basic facts you should know about it.

Możesz także dostosować monitorowanie dla niektórych aplikacji i natychmiast rozpocznie regularne przechwytywanie migawek ekranu telefonu. https://www.mycellspy.com/pl/tutorials/how-spy-app-remotely-monitor-someone-phone-activity/

казино

гама казино